Jason Davis • Nov 13, 2014

LightSail Gets Burn Wire Redesign for Round 2 of Vibration Tests

The Planetary Society's LightSail-A spacecraft is less than three weeks away from an expected go/no-go decision on whether the CubeSat will be launched into space for a shakedown cruise next year. Vibration tests in late October revealed a handful of problems that are being corrected. The most troubling of these was the spacecraft's solar panels, which managed to jiggle open on the shake table. A closer look by the LightSail team revealed the burn wire responsible for releasing the solar arrays was broken. To fix the problem, Ecliptic Enterprises Corporation created a new burn wire design. Tests of the new design are already underway. If all goes well, LightSail-A will go back into vibration testing later next week, and stay on target for delivery to Cal Poly in early December.

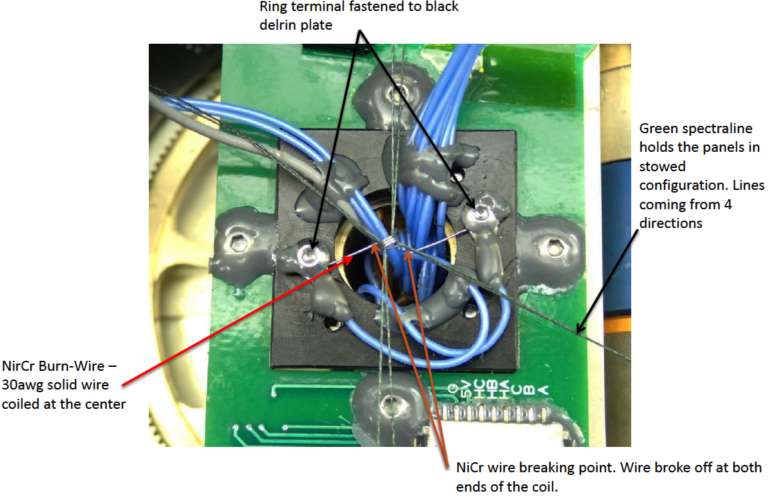

Each of LightSail's four solar panels are hinged on one side. Left untethered, they swing open into the deployed state you've seen in artist's concepts and testing videos. During LightSail's ride to space—as well as the on-orbit phase of the mission prior to sail deployment—the panels are held shut by a fishing line-like material called spectraline. The spectraline feeds through a small coil of Nickel-Chromium called a burn wire. When it's time for solar panel deployment, the burn wire gets a jolt of power—about 2 amps. The wire quickly heats up, and in just one second, it's hot enough to burn through the spectraline. The solar panels are free, and swing open into space.

Currently, each solar panel is tied to an adjacent panel, with the spectraline pulled tightly against the burn wire. Thus, when LightSail shakes violently during vibration testing (or during its eventual ride to orbit), the brunt of the force from the spectraline is sent into the burn wire itself. During testing, this caused the burn wire to break, which would be catastrophic during flight. Without the burn wire, the panels—and thus, the solar sails—would never deploy.

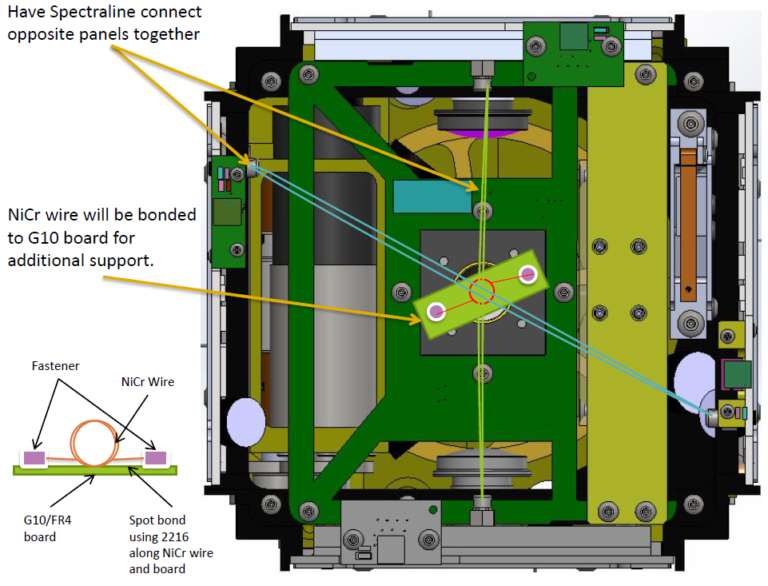

Ecliptic created a new design in which each panel is tied to its opposite (rather than adjacent) panel, reducing the amount of force on the burn wire. The thickness of the wire, which is currently 30 gauge, is being increased to 24 gauge. Finally, the wire is being bonded to the spacecraft with additional epoxy.

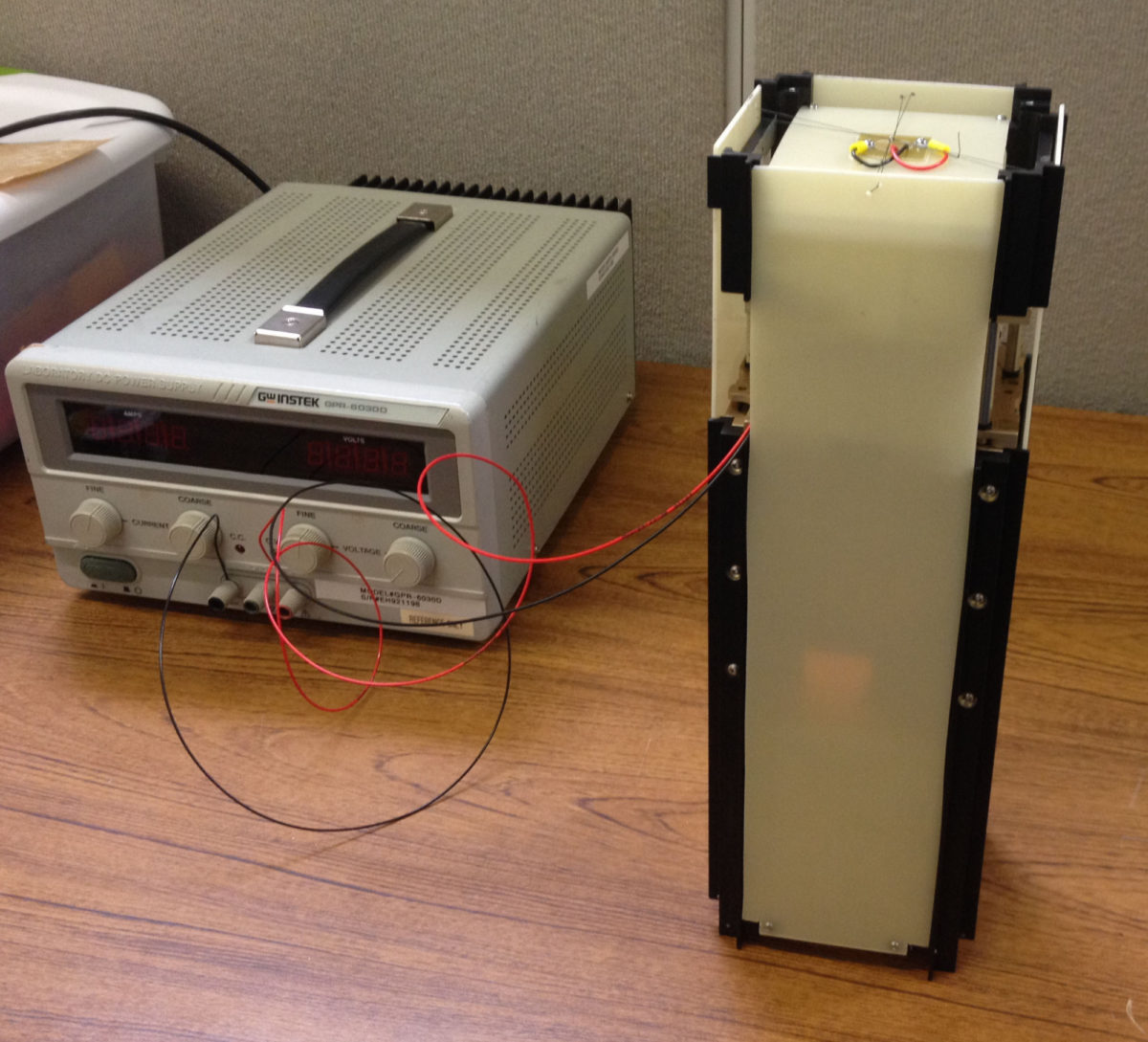

Riki Munakata of Ecliptic said the new configuration is currently being tested on a mockup structure, pictured here:

Next week, the Ecliptic team hopes to implement the new design on the flight unit. They will take the spacecraft from Pasadena back to Cal Poly for another vibration test. After that, LightSail makes a trip through the thermal vacuum chamber.

And if all that works? Cal Poly will take the spacecraft and integrate it for launch. Stay tuned.

Support our core enterprises

Your support powers our mission to explore worlds, find life, and defend Earth. You make all the difference when you make a gift. Give today!

Donate

Explore Worlds

Explore Worlds Find Life

Find Life Defend Earth

Defend Earth