Jason Davis • Jul 23, 2014

LightSail 1 Has a Blown Radio Amplifier. Now What?

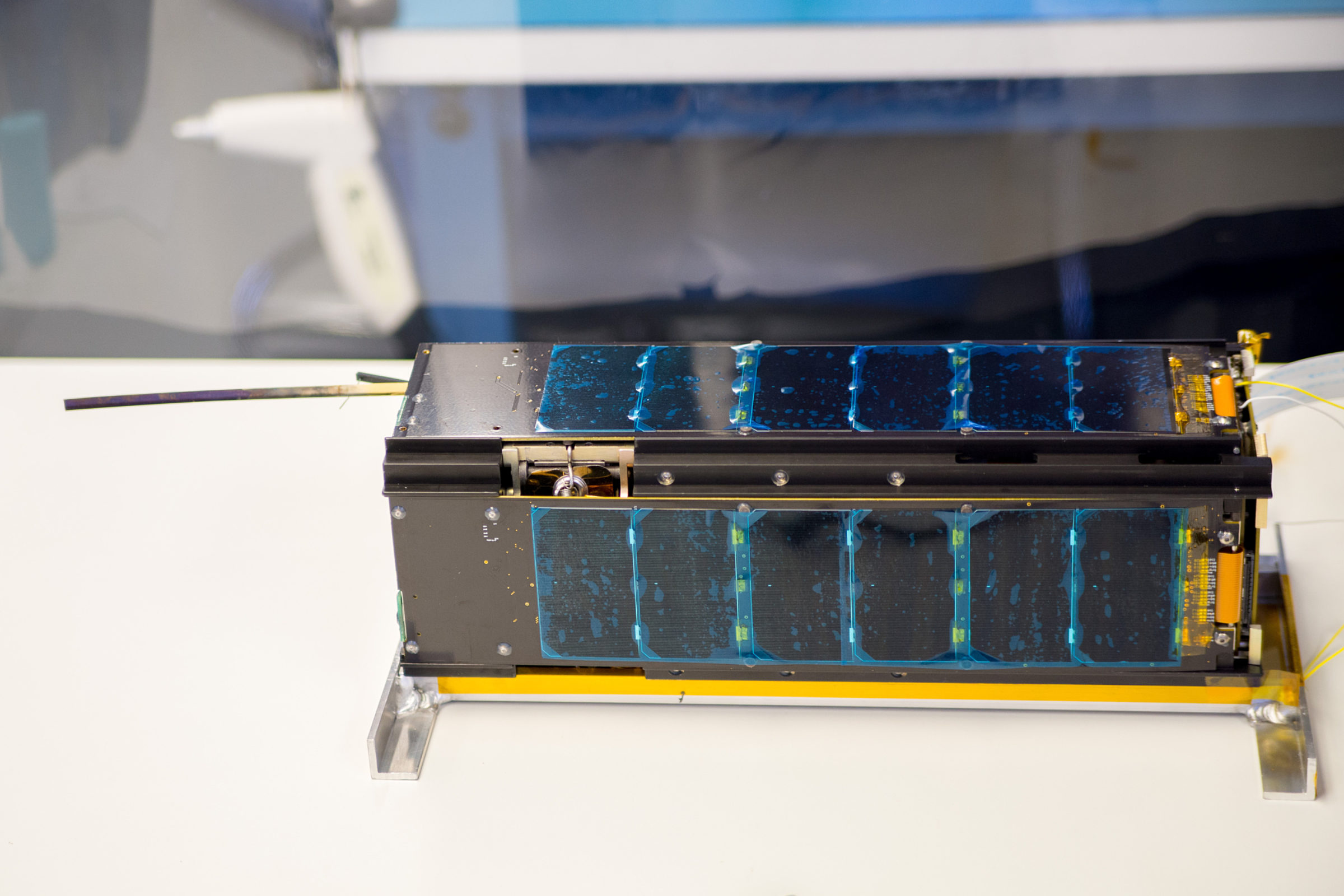

LightSail 1, The Planetary Society's solar sailing spacecraft slated for a possible test flight in May 2015, has a blown radio amplifier. While this doesn't affect the project's full-fledged 2016 mission that will fly on SpaceX's Falcon Heavy rocket, it adds an unwelcome obstacle to the test mission's ever-shortening timetable. The LightSail team has less than a month to repair the radio, figure out why it failed and prepare the spacecraft for a battery of tests. The LightSail 1 test mission is still on, but its schedule margin is now razor-thin—any new snafus could ground the flight.

LightSail talks with its ground stations at Cal Poly San Luis Obispo and the Georgia Institute of Technology using a simple antenna system tuned to 433 megahertz. In the spacecraft's avionics section, the main circuit board connects to a smaller 'daughterboard' containing a radio and amplifier. A radio frequency (RF) connector snakes off the daugherboard, down through the middle of the spacecraft and into a deployable antenna at the spacecraft's base. The antenna is coiled and stowed beneath a small hatch held shut with burn wires, which will be commanded to heat and sever in space. When that happens, the coiled antenna will push open its hatch and pop out perpendicular to the spacecraft's bottom side.

LightSail doesn't need an amplifier to send signals, but the signals aren't very strong without it—certainly not powerful enough to talk to a ground station zipping beneath LightSail at 8 kilometers per second. In fact, LightSail's unamplified radio signal fades into background noise just a few meters from the spacecraft.

According to Tyvak Nano-Satellite Systems, which manufactured LightSail's radio board, there are two quick ways to destroy the amplifier: transmit at full power while the antenna is coiled and stowed, or transmit at full power without the antenna attached at all. In either scenario, the amplifier generates a lot of power that has nowhere to go, and self-destructs. Alex Diaz, who works on LightSail's software and electronics, said something like this happened a couple years ago when LightSail first received its radio system. In that instance, a faulty RF connector leading to the antenna caused the amplifier to blow.

Since this is a known issue, the team is careful to avoid commanding LightSail—as well as its engineering test model, BenchSat—to transmit at full power while the antenna is stowed or disconnected. However, the spacecraft has a lot of automated processes that perform background tasks, such as the transmission of beacon packets that tell the ground where the spacecraft is. During the past several months, the LightSail team has been overhauling the spacecraft's software and electronics systems, shaking out bugs. Is it possible that an automated, full-power transmission command is buried deep inside the system? That's the question Diaz and the team are currently trying to answer.

Exactly when the amplifier died isn't known—the problem could have gone undetected for months. During lab tests, BenchSat is often configured to act as a ground station for LightSail 1. The two units usually sit in close proximity during these tests, meaning they've been chatting with each other just fine without the aid of an amplifier. Only now, as the mission enters the home stretch of testing, has the problem become apparent.

A couple weeks ago, BenchSat was being tested at the NASA Ames Research Park outside San Francisco, Calif. While BenchSat was transmitting, Diaz measured its over-the-air signal strength using a spectrum analyzer. This isn't the most accurate way to measure a radio signal—it's like modifying your car radio to determine how powerful the local FM station is. The best way is to plug the spectrum analyzer directly into the transmitter, but this isn't currently an option—both BenchSat and LightSail 1's radios are integrated with their surrounding hardware and lack the proper connectors.

The spectrum analyzer was just barely able to distinguish BenchSat's radio signal from other background radio noise. This concerned Diaz, but he also noticed LightSail's assigned spectrum was noisy—likely due to the presence of a nearby airport, Moffett Field. Diaz soon got a chance to test BenchSat again—this time using the actual Cal Poly ground station. BenchSat was able to receive commands from the station just fine. But when BenchSat transmitted, Cal Poly couldn't hear it, confirming that there was a problem with the radio. As a test, BenchSat was moved into the room that houses the endpoint of the station's antenna, which is mounted on the building's roof. At last, BenchSat's transmissions were received, but this meant that its amplifier was probably blown.

On its own, a dead BenchSat radio amp isn't a huge deal—it only costs about $150 to repair the radio board. But could the same thing have happened to LightSail 1? The spacecraft was already at Cal Poly, awaiting communications tests of its own. Diaz brought it out of storage, deployed its antenna and commanded it to transmit. Nothing. Once again, the radio signal barely registered above background noise on a nearby spectrum analyzer. Whatever happened to BenchSat also happened to LightSail 1, causing a blown amp.

Unfortunately, LightSail 1 can't skirt by with a $150 radio repair—mission planners generally avoid sending refurbished electronics into space. Instead, the spacecraft will get a brand new radio board from Tyvak for the cost of about $3000—not counting the engineering labor. Considering the total LightSail program budget is $4.5 million, it's a manageable setback. The bigger impact, however, is on the schedule.

Tyvak is rushing the order, but estimates it will still need two weeks to manufacture the radio board. In the meantime, LightSail 1 will be taken to Ecliptic Enterprises Corporation in Pasadena, where the faulty board will be carefully removed. Testing will be done to ensure the damage was localized to the radio amplifier. Installing the new board will take at least another week, cutting things very close to a sail deployment test tentatively planned for Aug. 12.

LightSail 1's solar sails have been packed in the spacecraft for about two years. Riki Munakata, an engineer with Ecliptic Enterprises Corporation serving as LightSail's integration and project lead, recently noticed that a spare engineering sail packed in prolonged storage is starting to stick to itself. Unlike LightSail 1, the engineering sail isn't stored in a rigorously controlled environment, so the team believes LightSail 1's sails will be in much better condition. However, the final verdict won't be known until the sail deployment test.

After that, LightSail 1 will move on to a full day-in-the-life test at Cal Poly, now scheduled for Aug. 20. This test takes the spacecraft through a simulated mission sequence that includes sail deployment, image capture and two-way communication. In September, the spacecraft will go through vibration and thermal tests that mimic its rough ride to orbit and the harshness of space. Oct. 1 is the due date for hardware and software modifications. In mid-October, LightSail 1's launch paperwork must be finalized, and the spacecraft goes into final storage on Nov. 1.

But before any of that happens, the LightSail team needs to figure out what caused the blown radio amplifiers on BenchSat and LightSail 1. They'll need to implement a fix to keep the problem from happening again. And they'll have to delicately disassemble and reassemble part of the spacecraft to replace the radio board—a procedure risky in its own right. If any new problems come up, there won't be much time for a fix—the test flight could be grounded. If that happens, LightSail 1 will continue to serve as a test spacecraft, paving the way for LightSail-B's full solar sailing flight in 2016.

The clock is ticking. Can the team get everything done in time? Will the sail deployment and day-in-the-life tests go off without any major hitches? If so, LightSail 1 will fly in May 2015. We'll have to wait and see.

Support our core enterprises

Your support powers our mission to explore worlds, find life, and defend Earth. You make all the difference when you make a gift. Give today!

Donate

Explore Worlds

Explore Worlds Find Life

Find Life Defend Earth

Defend Earth