Stephen Kuhn • Jan 08, 2013

Curiosity's Scoop Campaign, a Summary

As Curiosity makes progress through a long list of First-Time Activities (FTAs), the certification of much of the core sample processing capability has embodied the caution and incrementalism we use to dilute complexity and risk. In pursuit of this FTA, from sols 60 to 99, Curiosity remained immobile - though by no means inactive - at the Rocknest site, in what must appear from the outside an agonizingly slow pace of operations.

In partial rebuttal (for, to be honest, I feel this agony myself), and to give some context, the arm Rover Motion Counter (RMC) in the Rocknest site frame alone ended up a proud 4808. As it increments at the start and end of each arm move, we commanded single joint or compound movement of the arm 2404 times. By comparison, at the end of the nearly yearlong, storied journey Opportunity made through Victoria Crater, the counter for their arm (or Instrument Deployment Device) stood at 2303 (courtesy of the indefatigable MER and MSL veteran Vandi Tompkins). Noting that MER's counter increments only once for each arm move, it can still be said with some conviction that we kept busy at Rocknest.

Notwithstanding any numeric measure of complexity, there were constraints and surprises that together conspired to contribute to the length of our stay. Here I attempt to provide an engineer’s description of Curiosity's first sample acquisition and processing activities on Mars.

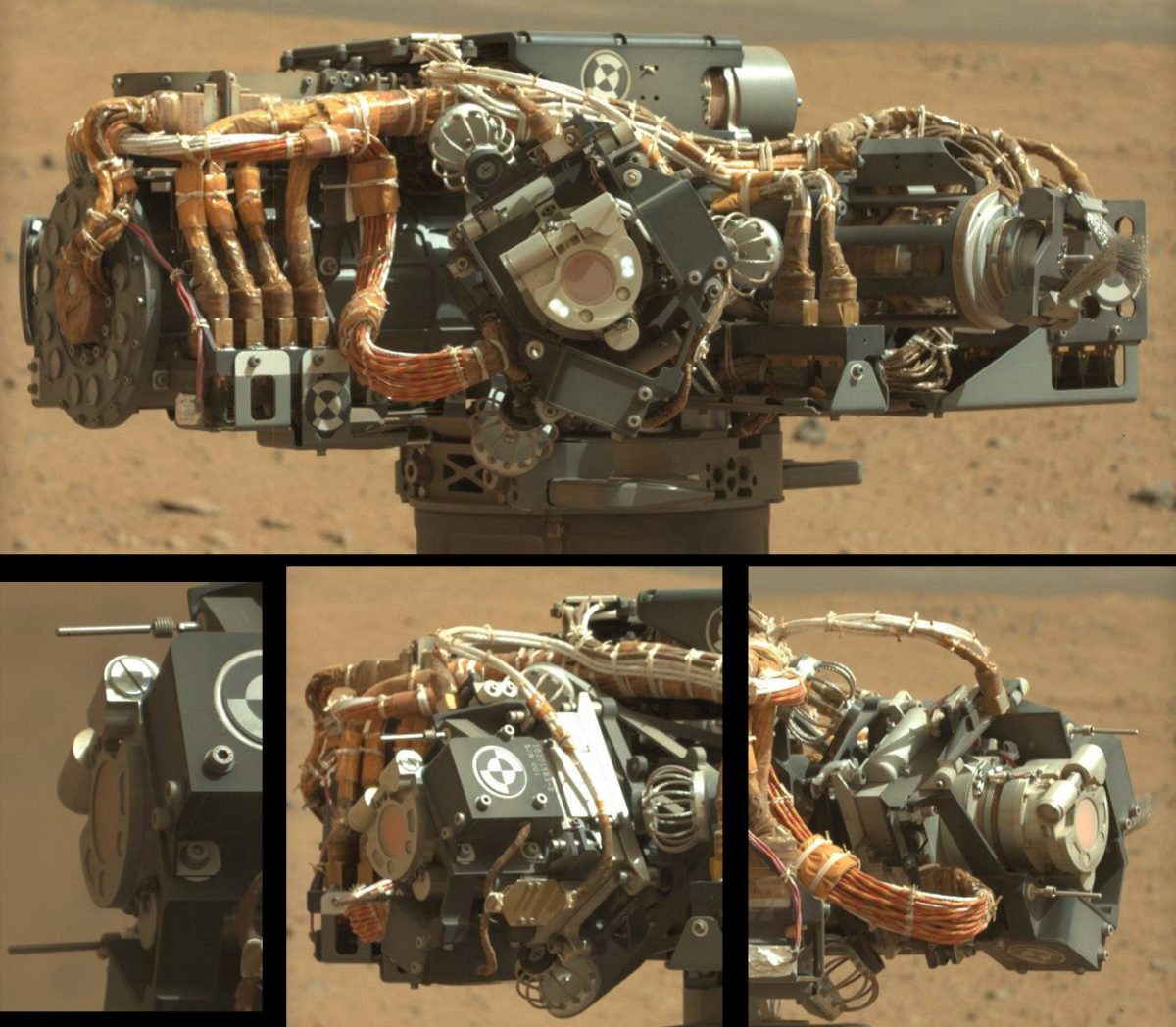

First, for those entirely unfamiliar with Curiosity's Surface Sampling and Science (SSS) hardware, including CHIMRA and the robotic arm, refer to Daniel Limonadi's introduction here. CHIMRA scoops and processes sample, as acquired from either the drill or scoop, and is situated on the turret at the end of the arm. It contains the scoop, the two paper-thin sieves (one with 150um and one with 1mm holes, for the two different sample processing paths), vibrating (vibing) and thwacking mechanisms, and several passages and partitions. In concert, these are used to portion and drop sample to the instruments or the observation tray and to clean up as best we can afterwards for the next sample. It's quite a neat bit of engineering, interacting as it must with a wide variety of sample with properties that can't be fully known. It performs its many functions robustly and in a tight volume, with as few actuators as possible.

There's a great paper by the original CogE (Cognizant engineer) and chief designer about the challenges and considerations that went into its design, as well as more detailed description of its operation and the two sample paths, here (PDF). Another great paper with a broader view of the sampling chain can be found here (PDF). Malcontents who like their details gory, rejoice, and I'll save myself the trouble. One detail is worth distilling, however. The end product of CHIMRA's labors - an aliquot, or single portion of sample - is a mere 50mg or so (see here for a view of the 150μm path’s portion hole). This amount is adequate in relation to the size of the instrument hardware that ultimately holds sample for analysis. However, it makes more challenging the task of guaranteeing that a prepared portion actually drops into an instrument funnel intact, most notably in the presence of wind and possible arm placement inaccuracy, among other potential sources of loss.

On that note, as a necessary prelude to describing how we scoop, we digress briefly into a description of the arm and its accuracy. Curiosity's 5-degree-of-freedom arm (comprised of azimuth, elevation, elbow, wrist and turret actuators) has accuracy limitations that are a function of gearbox backlash, thermal expansion, and mechanical deflection of the upper arm and forearm in supporting the ~30kg turret, in addition to the other ~70kg of arm hardware.

These are all modeled by onboard flight software in placing the arm and were characterized extensively through the use of metrology at our test facilities at JPL in ATLO (Assembly Test and Launch Operations). That process calibrated the uncertainty in the model, as expressed in several bins. Absolute attitudinal and positional accuracy describe the error in aligning and placing a tool frame at the commanded target in Cartesian space. Relative accuracy describes the error in commanding a relative position change. Absolute repeatability describes the variance as we command back to the same target. So, there's a component of total system accuracy that lives with the arm. Another component is our ability to accurately resolve the terrain. These surface meshes are typically created with stereo pairs of the NavCam and HazCam photos (though MAHLI and the Mastcams are capable of some beautiful color meshes as well, and HiRise meshes also exist). Anyone who’s seen an RSVP animation (Rover Sequencing and Visualization Program) has seen these meshes composing the terrain. Here is an example.

Predictably, there is some inaccuracy here as well. The arm and terrain mesh components of inaccuracy are additive in the ability to place a tool or instrument on the turret at an absolute distance relative to a feature on the terrain.

When we scoop, we place the arm at a commanded location above the surface and then move the scoop about its axis in an arc. The arm remains stationary, as its actuators are much more powerful than that of the scoop and could do physical damage to the scoop hardware. You can also the arm in position for our fifth bite at Rocknest in this Hazcam photo:

We enforce an allowed range on the depth of a scoop's bite into regolith; too shallow, and we don't have enough sample; too deep, and some unlikely though conceivable hardware risks present, which are however esoteric enough that I'll gloss right over them. Suffice it to say, the window is fairly small, on the order of a couple of centimeters. It was smaller still for our initial acquisitions, which were bound for an activity meant to decontaminate the internal surfaces of CHIMRA. For these scoops, a greater quantity of sample is required, and our minimum bite depth was larger. In fact, the window is smaller than the three-sigma arm/terrain system inaccuracy described above.

We close our budget in another fashion, by using MaHLI as a rangefinder. Like the MastCams, MaHLI can make use of autofocus. Essentially, it takes many pictures at different commanded focus settings and compresses them. The resulting size of each of the compressed images is plotted onboard against the motor focus count for those images, and the setting resulting in the interpolated peak size is taken to be best in focus. An image is then taken at that setting. In other words, blurry pictures compress to a smaller size than focused ones. Calibration curves exist that map motor focus counts to focus distance.

On the ground, we use that focus distance to tell how far away the MaHLI tool frame actually was - in an arm configuration and backlash regime similar to that when we're in position to scoop. Based on this we adjust from what our commanded offset would otherwise have been. Note that there is a bit of uncertainty even in this method, as the turret instruments are mounted on wire isolators meant to dampen vibration, and these contain some hysteresis. However, the accuracy is quite good at close range, and the cautious initial deployments at Rocknest have turned out very nicely. Here's a few good shots of MaHLI, mounted on its wire isolators:

As an aside, the turret-mounted APXS contains a contact sensor (a spring loaded plate with a contact switch) for sensing the surface. We make use of it regularly on rock targets, but have not deployed on unconsolidated regolith of the sort we look for when scooping, though we have deployed on "proven" regolith conditioned by the ground pressure of the wheels, on sol 89. MSL's APXS contact sensor shares design heritage with the Mars Exploration Rover Mössbauer spectrometer contact sensor, which has seen use on unproven regolith, but it requires a somewhat higher ground pressure to trip.

As the scoop completes its arc, it creates a bow wave of sample that typically ends with a larger quantity of sample in the scoop than we desire, if we didn't just kiss our minimum bite depth. In this context, a larger quantity than desired means that it meets or exceeds the CHIMRA design volume (a threshold related to how we prepare a portion) or, more fundamentally, is a quantity for which we don't have much experience testing. In other words, we attempt to instill some consistency into how much sample is ingested. This has an effect on how sample packs in the portion tube and how we manage and store it for contact science (the placement of APXS and MaHLI) and even for driving. Caching sample for driving allows for more efficient, opportunistic and interspersed dropoff to the instruments, letting SAM and Chemin sip from the cup now and again if they’ve not had their fill, allowing scientists to analyze their data in parallel as we make progress driving elsewhere. At Rocknest, much of this analysis had to happen serially – and for the first time – and many sols were spent on it, with the inevitable hiccups that were purely additive to the schedule.

The way we arrive at this more measured amount of sample is by "vibing to level". With a set of short vibe pulses (vibes of a couple seconds, barely hitting their target rates), we remove excess sample to level the amount in the scoop. Here are good pictures of the state before and after this process here. Below is a video of sample churning in the scoop as part of our first diagnostic here:

This behavior had varied in our two sample test venues (one is a full-scale rover mockup operated at ambient, the other is an environmental test chamber with a different arm) and is fundamentally non-linear. However, it ended up remarkably well-behaved and reasonably repeatable on Mars. It is well worth noting that this environmental testing is part of an entire parallel campaign at JPL called Qualification Model Dirty Testing (QMDT) with a team including many original designers that continues to work feverishly to scoop and drill a wide array of plausible materials under more realistic pressure, humidity and temperature (and to a certain extent electrostatic) conditions. Their characterization testing has informed most of the system sample processing architecture, as sample flows unrealistically at Earth ambient conditions compared to those of Mars.

Vibe dynamics (which plays a significant role in how sample flows and packs) are somewhat tricky. One of our commissioning phase activities attempted to characterize vibe dynamics in a couple of critical poses for comparison, to confirm that the behavior on Mars was not too dissimilar from our experience here on Earth. We don't have accelerometers on the turret, so we read the tea leaves of vibe actuator current plots over a set of ascending voltage step functions, looking for discontinuities indicative of resonant peaks. The vibe pulses help us to discretize the leveling and tend to remove sample more predictably, reducing the impact of variability in dynamics. Vibe dynamics depend primarily on vibe rate and arm orientation (and by extension the axis of rotation of the vibe actuator relative to the arm, as vibe is induced by a spinning eccentric mass). As such it is infinitely variable. On Earth, we acclimate our ears to this range, and speak of "well-behaved vibe" (something like a raspy blender) and "naughty vibe" (something like a lilting two–stroke motor). There's a pretty wide spectrum with a number of variations on the theme.

For our first four scoops (but not for the fifth), we enforced a conservative ground-in-the-loop process before closing the scoop, assessing images to confirm that we didn't have pebbles on the lip or in the scoop and that our scoop sample volume was appropriate. This self-imposed cycle cut the day’s arm activities short and contributed another component to the length of our stay (driven to a large extent as it was by fully completing a set of arm activities). Furthermore, the amount of arm activity per sol is still modest, at a few hours or so a day. In large part, this imposes a ceiling on perceived complexity, to which many in the review process are sensitive, especially for first-time activities.

But there were additional constraints that tended to pare a sol’s activity to size. Every day, each command has to be reviewed three times along the way in the sol’s planning cycle. We always plan around our one to several Odyssey and/or Mars Reconnaissance Orbiter afternoon communications passes, during which other activity stops. These passes can be variable in number and spacing with each new sol and make robustness to sol slips and any sort of activity packaging optimization a challenge. Conservative projected actuator heating windows mean we only start arm ops near mid-sol currently. Cleanup windows and duration margins have to be allotted for each comm pass and sleep/wake cycle. Margined power budgets can sometimes cut arm activity short, especially when performing instrument analyses overnight, which is otherwise a period of battery recharge. As we often were taking images, suitable lighting dictated that we could not operate into the early evening. The conservative use of windows for dropoff with the least disadvantageous wind effects also tended to limit the day’s arm activities. There were several additional ground-in-the-loop cycles for some planned and unplanned activities. In addition, I’ve not even scratched the surface of all the science activities, which had their own set of constraints that had to be interwoven with those of the engineering activities, with some sols at Rocknest allotted entirely to instrument checkouts and prep, or remote or contact science.

Decontamination of the polished interior surfaces of CHIMRA was a primary purpose and consumer of time at Rocknest. Terrestrial organic contaminants composed of fine particulates in the air are deposited in even the best of clean rooms here on Earth. Those remaining attached through launch and EDL loads require additional stimulus for removal. That stimulus is essentially an extended period of contact with vibrating sample, in turn on all the amenable facets of CHIMRA's interior. Contaminants are scrubbed loose to be swept away and diluted into sample dumped to the side of the rover. Reducing the concentration of these particles in this decontamination activity helps to prevent subsequent, undesirable removal into sample bound for an instrument during our nominal sample preparation activities, which also make use of significant amounts of vibe. The SAM instrument is extremely sensitive, and without the steps we took, our models indicated that we could far exceed their threshold for allowed contamination. These models were calibrated by swab tests in ATLO, projected outgassing and other effects during launch, cruise and descent, and empirical testing of contaminant transfer coefficients under vibing sample. (Note that CHIMRA’s interior surfaces are but one of several potential vectors for introduction of contamination into SAM).

Not only did we perform this activity once, we executed it three times to meet our target, with interstitial thwacks to further help clear loosened contaminants. These three iterations, from acquisition to the cleaning and imaging performed at the end of a cycle, took nearly 20 hours of execution time (performed across 10 or so nonconsecutive sols). And this bespoke activity was about as complex from a commanding and sample management perspective as our entire nominal sample process chain, which has been in work for years. Finally, we spent many sols acquiring the fifth scoop and dropping to SAM repeatedly, again to Chemin, and to the observation tray for APXS and MaHLI analysis. It adds up.

As part of the dectontamination activity, on sols 64 and 78 we actually took two videos with the left Mastcam of sample falling from the portion tube, up high and to the port side of the rover where we could see, as opposed to directly over the inlet covers. They were taken at about 9 to 10 frames per second (frame rate is a function of several factors, and this particular rate is a product of some compromises).

The videos include an annotation of the location and sizing of the instrument funnels relative to the portion hole (with lateral placement uncertainty in the arm in yellow), as well as a diff of each frame against the average across the video. You see the portion door opening, followed several seconds later by the start of vibe (as the turret starts to shake more, around 0:17). The shape of the portion hole has what we call a slight "inverse flower plot" conical shape to it (the hole is 3mm in diameter at its top, and 4mm at its base), which is meant to help encourage the formation of a plug of sample (as can be seen in the first drop). The idea is that the more the sample acts like a single body as it falls, the more favorable the square/cube relationship of drag force to inertial resistance; in other words, the finer the particle, the easier it is to blow away. Interestingly, the behavior across drops was somewhat different. In the first drop (our first prepared portion, with clean surfaces prior, on sol 64) sample did not drop until vibe was turned on; in the second (sol 78), sample started to drop as soon as the portion door was opened.

Subsequent characterization tests of sample behavior over the O-tray appear to have reverted to the original behavior in which sample only dropped when vibe was turned on. Sample dropoff is not a closed-loop process (there are no scales, cameras or photodiodes to document and quantify sample dropoff behavior). Aside from the presence of a signal in the science analysis itself, we have little to gauge success or calibrate a mass budget, but we do what we can with these diagnostics. For SAM in particular this is important, as the mass we drop off feeds directly into the quantification of absolute species concentrations in the sample.

One of the surprises of our scoop campaign was the presence of FOD (Foreign Object Debris) in the final context image we took of our first scoop, barely visible in the lower center-right here. It was subsequently imaged with MAHLI and deemed to be some polymeric debris from MSL, though competing theories existed as to its origins. A leading theory was that it came from the descent stage separation process (in which many cables are cut and debris generation is expected). It could then have been sequestered on the rover, perhaps somewhere on the arm/turret (which is replete with hiding places), until a particular arm orientation and/or perhaps the stimulus of vibe allowed it to be freed. Before continuing, we had to go through this diagnosis process (which included a far greater number of hypotheses) and convince mission managers that what we were seeing was not a part of any rover hardware that had an ongoing function (as if, say, those first few blurred pixels had obscured a screw). This added several days to our time at Rocknest. In addition, with this added sensitivity, the appearance in the second scoop trench of a light-colored particle resulted in dumping that scoop to perform an investigation. Subsequent MaHLI images indicated that the particle had been embedded and not deposited and hence was Martian, possibly a feldspar phenocryst. This cost us another couple Sols. Potential contamination is taken very seriously for an instrument as sensitive as SAM.

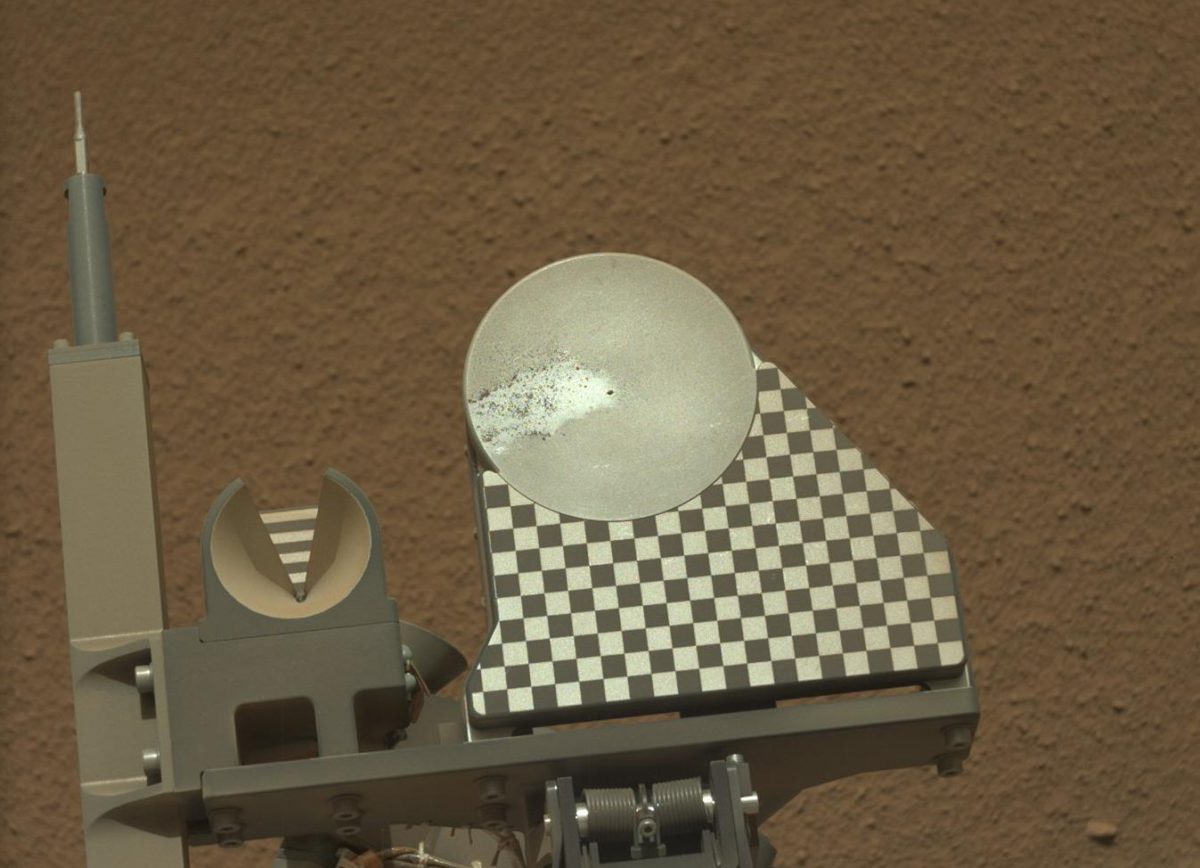

Another "surprise" was the extent to which we were typically unable to keep dropped sample from walking off the flat, smooth observation tray. The observation tray is used to assess sample properties against a known background – commercially pure titanium – typically prior to dropping to an instrument. We have seen some similar behavior in testing on Earth, though it was much less pronounced, and hence the surprise was one of degree. CHIMRA’s vibration is transmitted through the arm and into the chassis. It can be felt by touch even at the wheels. On the observation tray its effect is seen especially as we quickly ramp up to our target rate at the start of vibe and down at the end, through the resonant frequency of the bracket attaching the observation tray to the chassis.

Some time at Rocknest was spent dropping several additional portions using a nominal strategy, and returning to drop more using a characterization strategy in which we backed away and took Mastcam images at key points to see how sample had behaved. We also dropped to the observation tray a larger-than-standard portion (where this standard is the amount dropped to instruments) intended for APXS analysis. Note that the rover tilt at Rocknest was only 4.9 degrees, a fraction of the 20-degree design requirement for sample processing.

All in all, I think we had expected Mars to draw more blood than it has, though the fun has just begun, with drilling on the near horizon. In 39 sols we accomplished a fair amount, and with a minimum of avoidable error. (There were no faults or command error recoveries in SSS mechanism operation at Rocknest, across thousands of commands). That's a testament to the quality and ingenuity of those who designed and operate Curiosity, a remarkable group of people on most days.

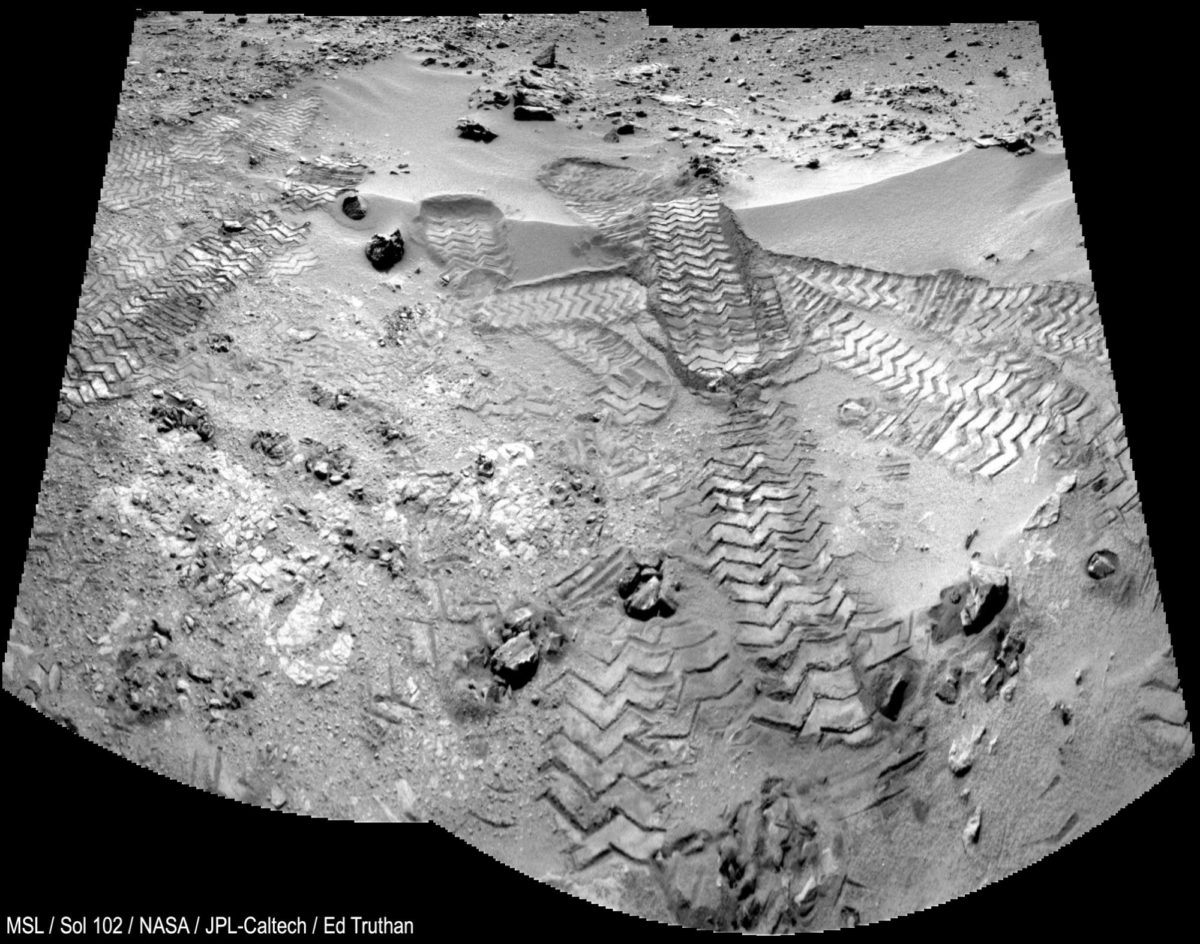

The epitaph to our lengthy sojourn at Rocknest was this. To avoid rocks and optimize the behavior of visual odometry, mobility rover planners did drive over and erase nearly all evidence of the scoops we took there. Fortunately, few of us are afflicted with any great amount of sentimentalism, least of all the rover drivers, for whom deigning to preserve a few subtle bites amidst their cacophony of tread marks seemed aesthetically absurd. To each his own, and we look forward to repopulating the surface in the future.

Thanks to Dan Limonadi, Emily Lakdawalla, Vandi Tompkins and Guy Webster for their gracious help and edits. Any questions are welcome.

Support our core enterprises

Your support powers our mission to explore worlds, find life, and defend Earth. You make all the difference when you make a gift. Give today!

Donate

Explore Worlds

Explore Worlds Find Life

Find Life Defend Earth

Defend Earth