Daniel Limonadi • Aug 16, 2012

Sampling Mars, Part 1: The Hardware

Curiosity is a mission not so much of firsts, but of panache, depth, and improvement. We have been to Mars. We have acquired and analyzed samples on other heavenly bodies. But we have never done it quite like this. As you know by now, Curiosity is a car-sized, mobile platform with state-of-the-art scientific tools, analytical instruments, and the biggest and most capable robotic arm that humans have ever sent to the surface of another planet.

In the coming months and years, there will be many stories about Curiosity and its mission to explore Mars. Here I talk about the Surface Sampling and Science system (SSS), focusing on the components and how we expect to operate them on Mars. This is the initial entry of what will be a multi-entry blog. I will provide quick overview of the hardware, discuss some of our key challenges on the sampling system side, and then jump into plans for how we will carefully checkout the hardware and later operate it to acquire samples on Mars.

Surface Sampling and Science (SSS) – what is it?

From its inception, the Mars Science Laboratory (MSL), or Curiosity as it is more commonly known, was to be a mobile analytical lab to explore the past and present habitability of Mars. The planetary science community wanted a mission that could better answer whether or not Mars, either currently or in its past, could support organic life. To do this, Curiosity needed to get to the subsurface of the planet.

Why go below the surface?

One of the things we have learned from the last 40-plus years of Mars exploration is that the exposed surface of Mars is incredibly inhospitable to organic matter. Two main things contribute to the breakdown of organic matter that is exposed at the surface. Lacking much atmosphere or a global magnetic field, Mars suffers intense solar ultraviolet radiation and is unprotected from cosmic radiation. Also, its soil and airborne dust contain oxidizing compounds that quickly break apart larger molecules. To maximize the chance of finding protected organic matter, it would be best to dig tens of centimeters, or more, below the planet’s surface.

However, the sampling acquisition system architecture for Curiosity was constrained to be a relatively compact shallow subsurface sampling capability that could be carried by a rover. There were a number of factors that we tried to balance to maximize the overall chance of mission success. Successfully drilling bore holes in a distant planet is not a trivial engineering endeavor. The science community also wanted the ability to sample a variety of terrain types and features and to get to the best candidate targets. We also wanted to be able to take advantage of Mother Nature’s deep drilling operations -- impact craters -- just as Opportunity has at Meridiani Planum. Our system balances these desires for mobility and subsurface access with the technical risks and a responsible caution about sampling methods never before attempted on another planet, millions of miles away.

Many resources exist on the Web and in the in the literature (journal and conference papers) describing the specific elements of the MSL SSS system (Google is a wonderful thing, but the MSL pre-landing press kit is a good place to start). There are three major subsystems that make up the Curiosity SSS system:

- The Sample Acquisition, Processing and Handling subsystem (SA-SPaH)

- The Sample Analysis at Mars (SAM) Instrument

- The Chemistry and Mineralogy (CheMin) Instrument

The Sample Acquisition, Processing and Handling subsystem (SA-SPaH)

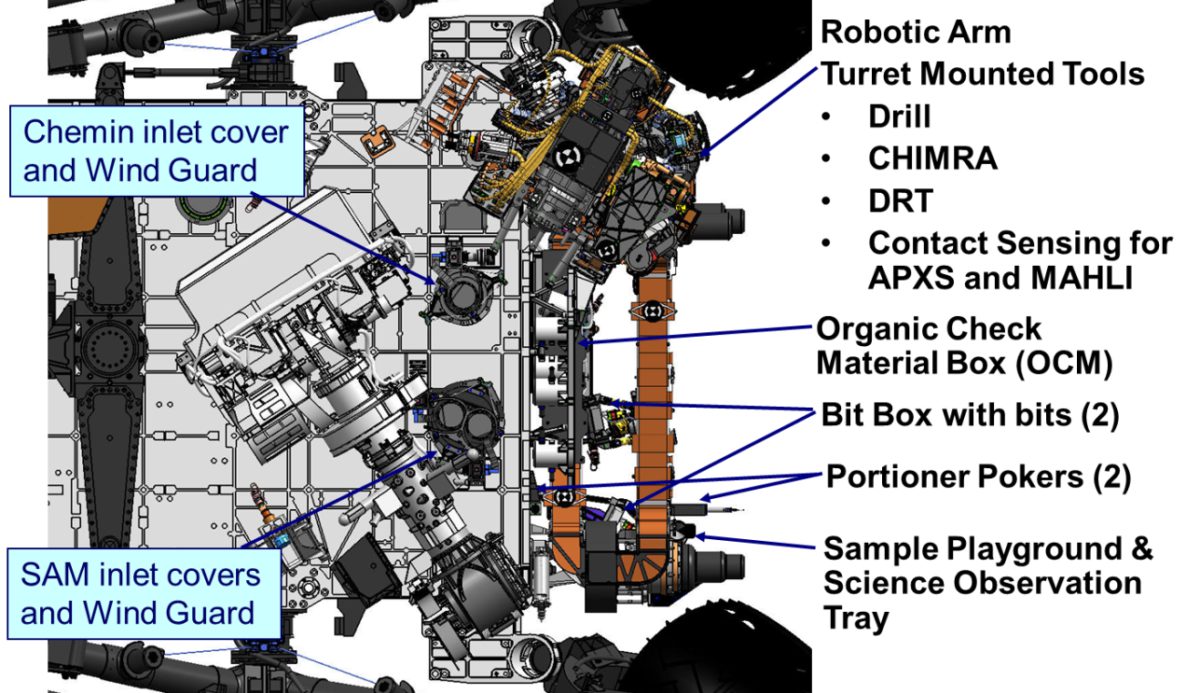

The SA-SPaH subsystem is comprised of the following: three motorized inlet covers for the instruments; a robotic arm having three turret-mounted tools; and some body-mounted, non-mechanized hardware.

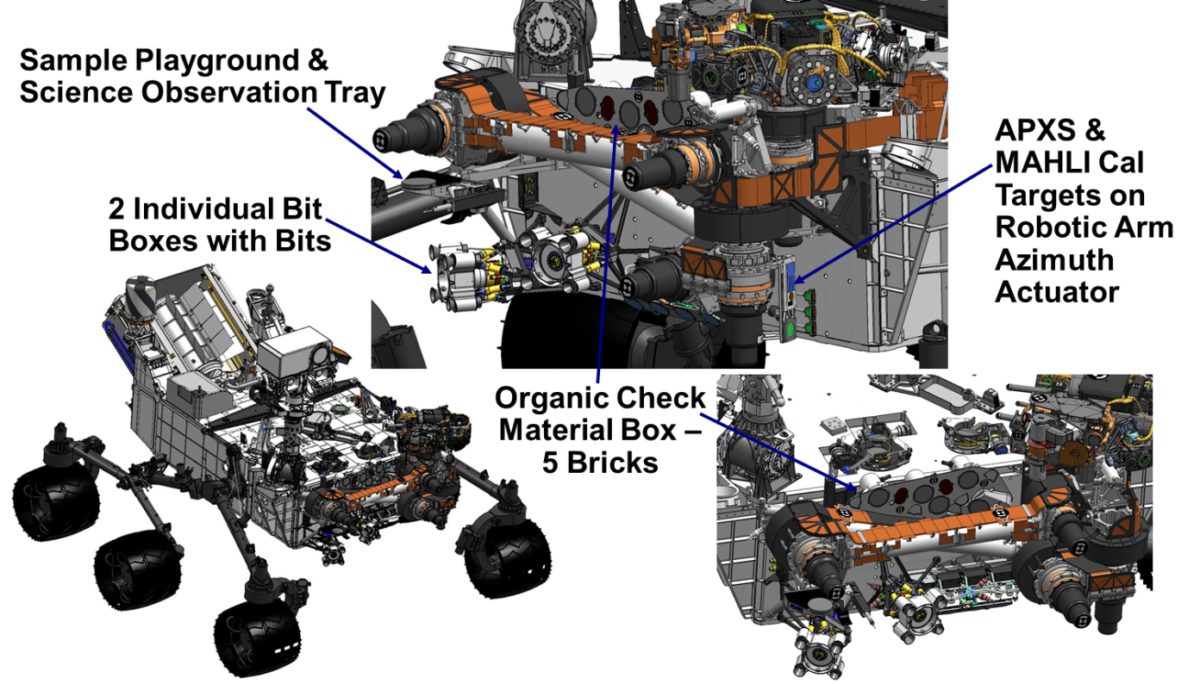

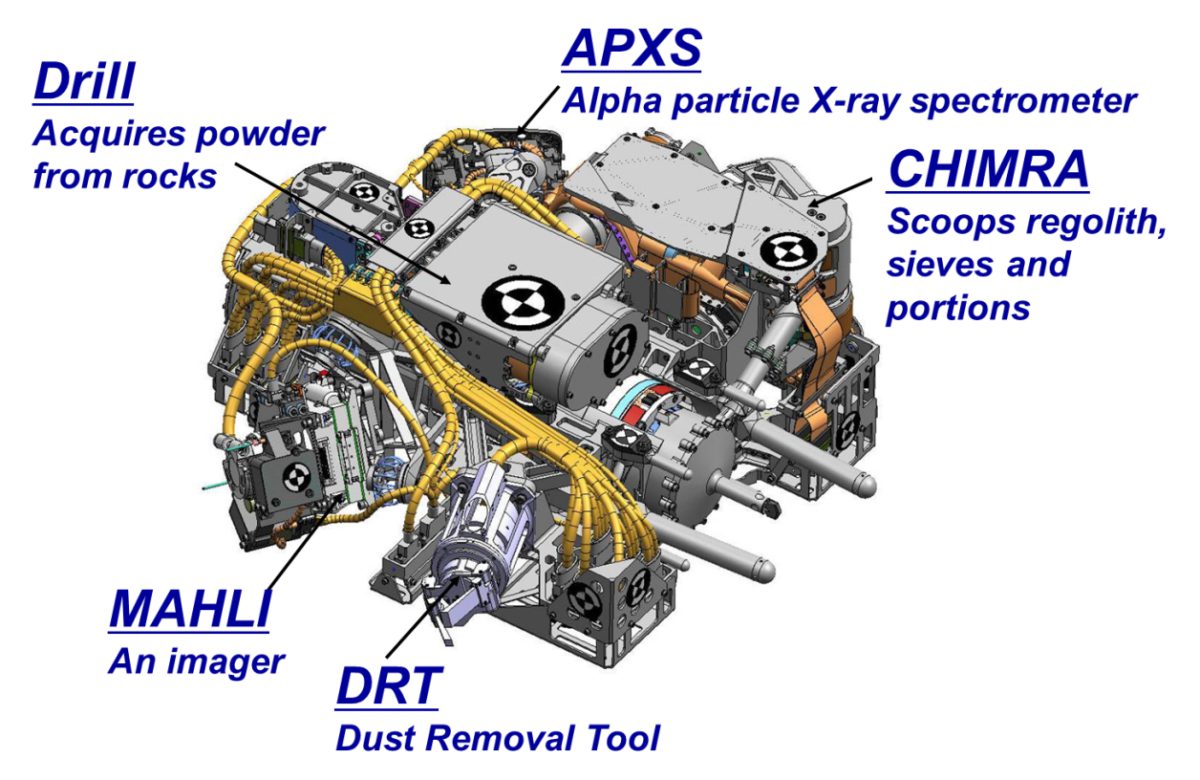

The robotic arm mass is approximately 70 kilograms, and carries a 30-kilogram turret at its end. The arm has five degrees of freedom (two each in "shoulder" and "wrist", and one at the "elbow") The three turret-mounted tools are a drill; the sample processing hardware; and a dust removal tool. The sample processing hardware includes an integrated regolith scoop. This sample processing hardware’s full name is the Collection and Handling for In situ Martian Rock Analysis tool, or CHIMRA—acronym engineering at its best. (It's pronounced like Chimera, the multi-headed beast of Greek mythology.)

Also on the turret, but not part of SA-SPaH, are two science instruments: the MArs Hand Lens Imager (MAHLI, built by Malin Space Science Systems), and an Alpha Particle X-ray Spectrometer (APXS, supplied by the Canadian Space Agency). There are also several non-mechanized tools mounted on the rover body: drill bits, a sample playground, and portion pokers. The two spare drill bits can replace the primary drill bit if the primary bit dulls or gets stuck in the ground. The sample playground includes two different trays to drop material onto and a test funnel to drop material through. Engineers and scientists will use this sample playground to mechanically test and observe collected samples.We also include two “portion pokers”. These portion pokers are basically spring-loaded nails that we hope to never use, and serve as an unclogging tool of last resort.

The SA-SPaH will acquire powdered rock samples by drilling to 5 centimeters (2 inches) deep inside rocks, or by scooping up loose regolith (that is, soil) from the Martian surface. This acquired material is then sieved, either through a 150-micrometer (roughly the width of your hair if you have black hair) or a 1-millimeter (about the diameter of a thick pin) sieve. It is then portioned and dropped into the two analytical lab instruments.

For the 150-micrometer path we can generate multiple portions from a single drill or scoop acquisition – generally at least six portions, and typically significantly more than that if needed. For the 1-millimeter path we can only generate a single portion and basically discard the rest of the sample during the portion creation process. We would need to acquire another sample to generate a second 1-millimeter portion. Only scooped samples, not drilled samples, will nominally be passed through the 1-millimeter path.

Support our core enterprises

Your support powers our mission to explore worlds, find life, and defend Earth. You make all the difference when you make a gift. Give today!

Donate

Explore Worlds

Explore Worlds Find Life

Find Life Defend Earth

Defend Earth