Jatan Mehta • Apr 17, 2018

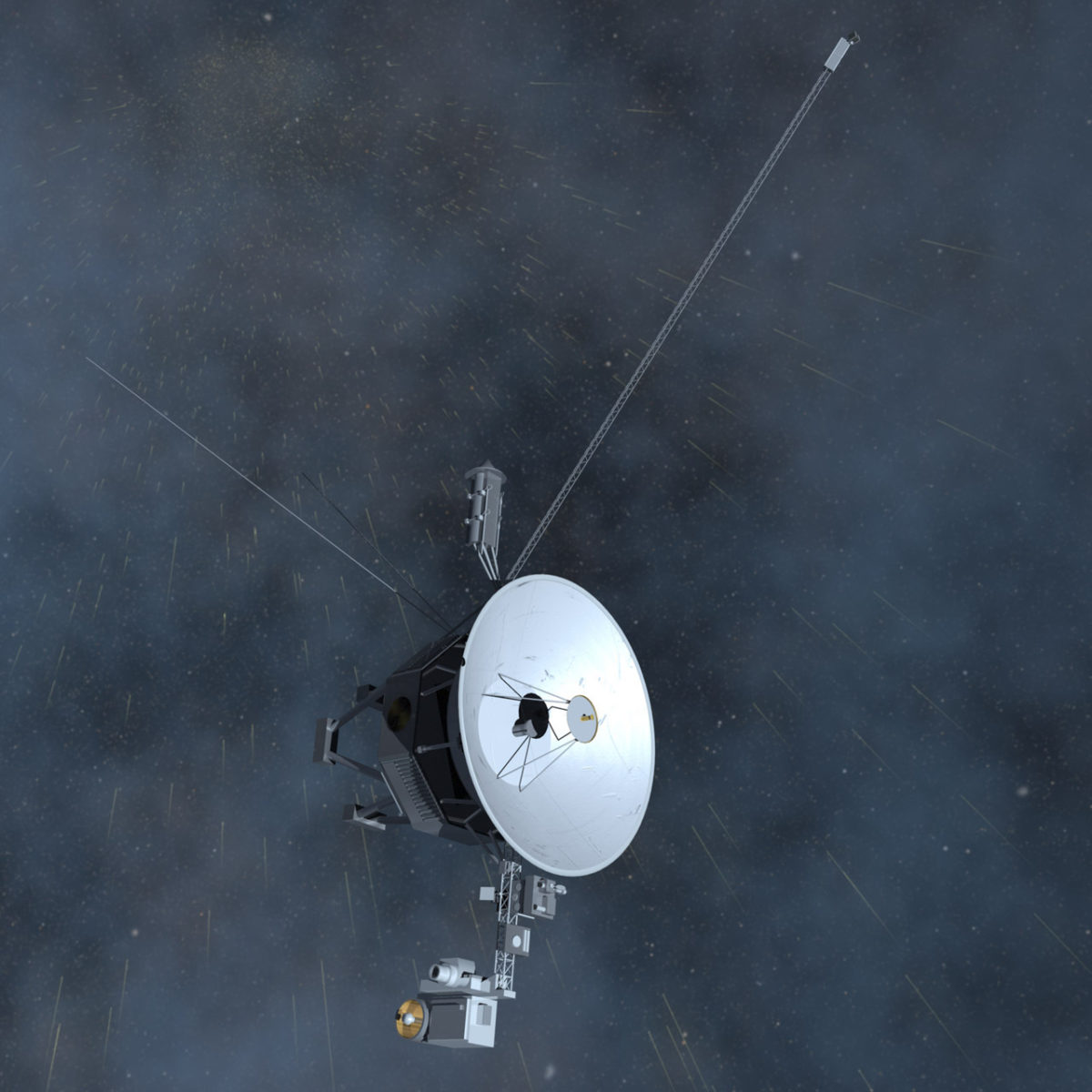

Space grade electronics: How NASA’s Juno survives near Jupiter

Six space missions that reminded us space exploration is hard

This article originally appeared on the Team Indus blog and is reposted here with permission.

November of 2011 was a particularly exciting time for planetary scientists. Russia had launched its Phobos-Grunt spacecraft, designed to land on Phobos—the first ever attempt on the largest Martian moon. What was even more exciting is that the spacecraft was going to return about 200 grams of sample from Phobos’ surface! Science!

The launch was successful, but the spacecraft never left Low Earth Orbit (LEO). The spacecraft failed to fire its engines and its orbit decayed in a matter of weeks. Pulled by the Earth, it plunged into the ocean, resulting in a total mission failure. Along with the spacecraft, China’s first Mars orbiter, Yinghuo-1 and The Planetary Society’s LIFE experiment onboard were lost, too.

So what went wrong? The failure report revealed that the spacecraft’s electronic components were neither qualified to be used in space nor tested prior to launch. The loss of Phobos-Grunt and the science it could do was a bitter reminder of the unforgiving nature of space exploration. Cutting corners in spacecraft development and testing to save some costs will cost us even more in the end.

In this article we take a look at how electronics of spacecraft are built to survive the harshness of space environments and some interesting peeks into different space missions.

Hardening electronics for space usage

Build to last

Electronic components used in spacecraft must be built to survive the harsh space environment and function reliably in it. The US Department of Defense mandates over 100 tests to ensure reliable operation under mechanical stress, wide temperature fluctuations, and intense ionizing radiation. All space-grade electronic components must be individually qualified, as opposed to the sample testing common in commercial or industrial applications.

It is for the same reason that all the electronics in our TeamIndus spacecraft’s IAU (Integrated Avionics Unit) are fully space-grade. So are vital components like the star sensor. Other electronic systems like the lander image processing units and the rover cameras are built to be fault-tolerant.

To ensure the desired reliability, system designers can’t use the latest and greatest chips. If we take a look at which CPUs are used in spacecraft, we will find that most of them are very old designs, some even dating back to the 1990s. It's critical to use something that has been tried and tested, which we know will work.

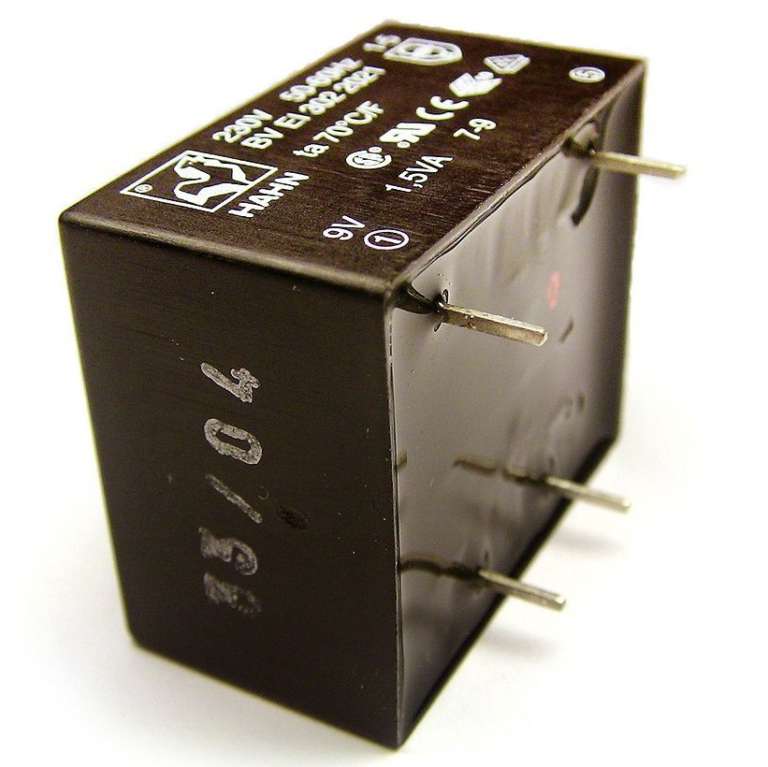

Electronic components are hardened for space usage using some of the following techniques:

1. Potting

Severe vibration during a rocket launch can induce mechanical stress on the electronics and damage them. The process of potting involves filling the electronic assembly with a solid or gelatinous compound to resist shock and vibration.

2. Silicon on insulator

Chips for space usage are manufactured on an insulating substrate instead of a silicon one, allowing them to be more radiation-resistant and fault-tolerant.

3. RAM types

Static RAMs (SRAM) are preferred instead of Dynamic ones (DRAM) because they are less power-hungry. This is crucial for when spacecraft go into low-power modes but need to continue sending telemetry data.

4. External shielding

An external shield (like lead) around the electronic components reduces exposure to radiation, thereby increasing life span of the mission. This is particularly useful in long-term missions like New Horizons which is currently en route to a Kuiper Belt Object.

The size of electronic components qualified for space usage is thus usually much larger than commercial/industrial ones.

Effects of radiation on spacecraft electronics

Even with all of these modifications to make electronics space-grade, they can still suffer in space from intense space radiation. A wide range of effects, known as Single Event Effects (SEE), can cause operational issues.

- Ions in space radiation interacting with the chip components can flip the states of bits and cause memory errors.

- A high-energy ion or proton passing through the inner transistor junctions can cause latchups, leading to short circuits.

- Similarly, this high-energy particle radiation can also let electrons loose in a circuit, causing irreversible damage.

Memory losses, code execution sequences going haywire, latchups, etc. are all undesired events in a successful space mission. Some of these can only be overcome with a hard reset, while some cause permanent damage. Spacecraft electronics must be built with all these factors in mind.

Apart from the Phobos-Grunt incident, let’s have a look at space missions which act as a constant reminder of the harsh, unforgiving nature of space exploration. (This article was inspired by Emily's recent piece on sample collection.)

1. When you lose your star sensors

India’s first lunar orbiter Chandrayaan-1’s star sensor failed to work after a few months in lunar orbit. The extreme exposure to solar radiation combined with other factors caused the backup star sensor to fail too.

The rest of the two-year mission had to be completed using the onboard gyroscope and constant corrections from the ground station. The mission was ultimately successful but it was a reminder that even space-grade components can falter.

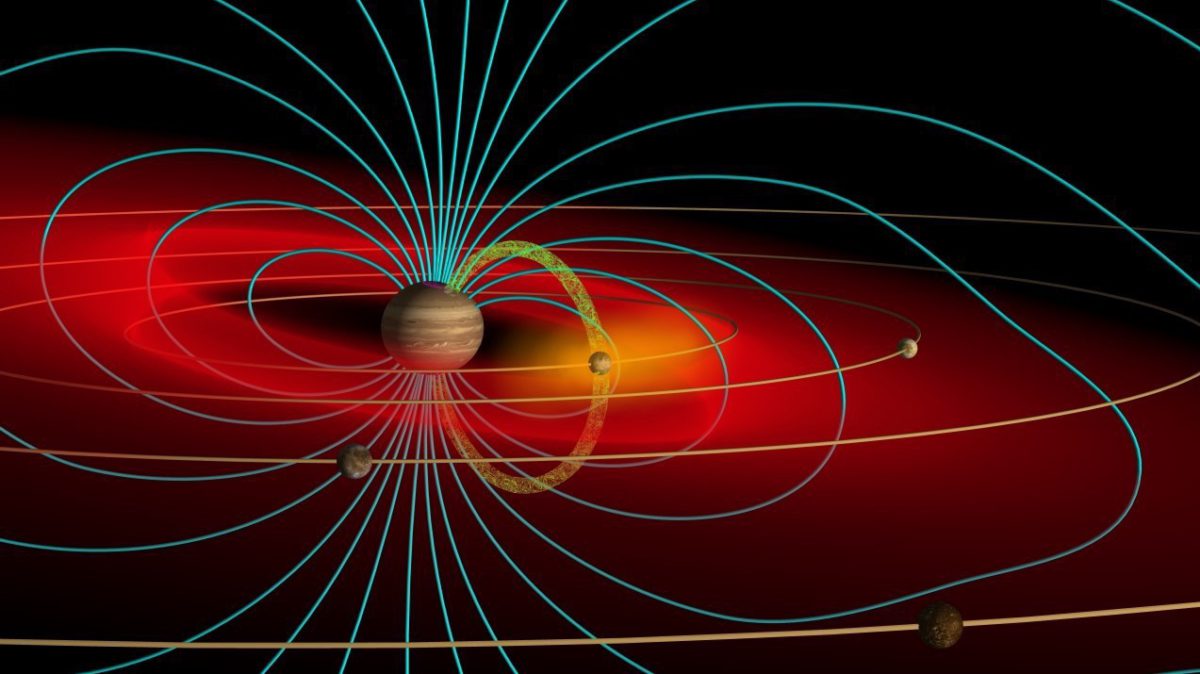

2. When you have six computers to complete one job

The Galileo spacecraft, designed to orbit and study Jupiter, had not one but six CPUs. Surviving in the radiation-riddled Jovian environment — which is orders of magnitude more intense than Earth’s — mandated that each major subsystem be controlled by its own CPU for fault tolerance. That way if one CPU dies, it only disables one major user-facing instrument.

Each of the CPUs used were the 8-bit RC 1802, clocked at 1.6 MHz. They were fabricated on sapphire (silicon on insulator), which is radiation-hardened and suitable for the intense Jovian environment. The processing capabilities of the Galileo spacecraft were equivalent to the classic Apple II computers sold a decade prior.

The use of redundant backup modules is a standard practice in spacecraft development to minimize issues. Despite these protective measures, Jupiter’s harsh environment caused more than a dozen anomalies to the Galileo spacecraft over time, including frequent resets of the onboard computer.

3. When solar flares damage your solar panels

On the way to the asteroid Itokawa in 2003, the Japanese spacecraft Hayabusa was hit by one of the largest solar flares in recorded history. The flare damaged the solar panels, thereby reducing their output. Not just that, the flare also took out one of the four ion engines of the spacecraft. The mission duration had to be reduced as a result.

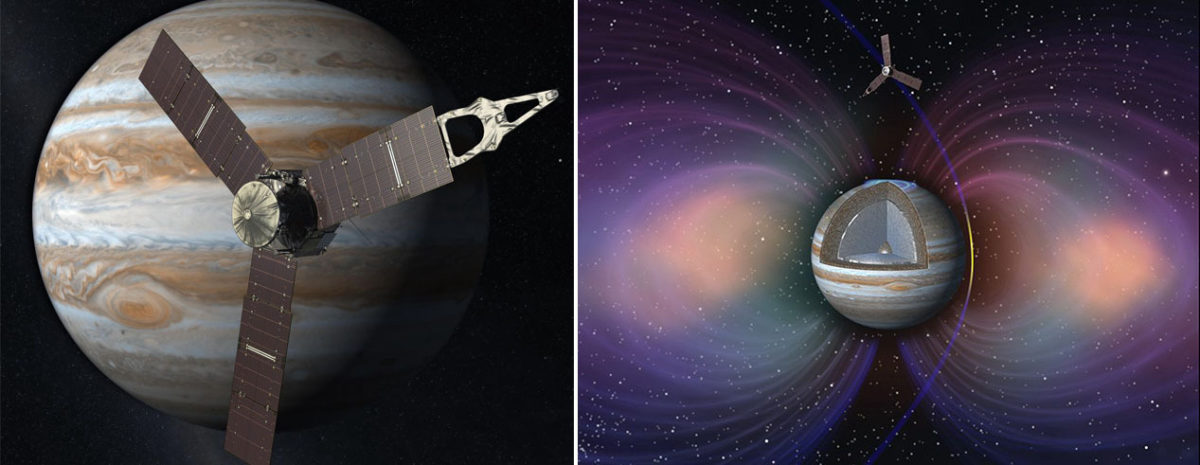

The excessive radiation damaged the junctions in the solar cells and was also a cause of concern when designing Juno, NASA’s spacecraft currently orbiting Jupiter closer than any spacecraft that went before. The engineers knew the solar panels would degrade with time due to the intense Jovian radiation. The risk was minimized to acceptable levels by using solar panel glasses twice as thick as usual and increased solar panel size for greater output.

4. Radiation hardening using RAD computers

One of the latest generations (in space grade terms) of radiation-hardened chips is the 32-bit RAD750 manufactured by BAE, based on the PowerPC 750 designed by IBM. It is designed to minimize losses even when facing extreme radiation from solar flares. Having a wider temperature range and 10 times better performance than the previous generation RAD6000, the RAD750 has been used in more than 150 space missions since launch, including everyone’s favorite Mars rover Curiosity.

Some of the other popular space missions powered by RAD750s include Lunar Reconnaissance Orbiter, Kepler space telescope, Solar Dynamics Observatory, and of course, the Juno Jupiter orbiter. Each RAD750 costs about $200,000.

As noted before, many missions have backup computers for redundancy and robustness against the failure of this crucial component. The Curiosity rover has onboard two RAD750 CPUs, one acting as a backup unit which took over when the first one faced issues with its flash storage.

5. The case of Juno and Jupiter

Designed to study Jupiter’s poles and go closer to the planet than any spacecraft before it, Juno is faced with challenges. It turns out that using individually-tested space-grade components, one of the most radiation-hardened CPUs, and making use of redundant components is still not enough to face the harsh environment near Jupiter, the planet with the largest magnetosphere in the solar system.

The RAD750 CPU is designed to withstand up to 1 million rads of radiation on its own, which is remarkable. But the mission is expected to expose Juno’s components to 20 million rads of radiation over time. That’s quite intense.

To protect the electronic components, the engineers built a protective armor shield built out of titanium that has centimeter-thick sides. This cubical vault reduces the radiation exposure to the electronic components by a factor of 800.

The shield is so important to the functioning of Juno that it gets its own name — Juno Radiation Vault.

“Without its protective shield, or radiation vault, Juno’s brain would get fried on the very first pass near Jupiter.”

-Scott Bolton, Juno’s Principal Investigator

Even then, Juno is expected to cease functioning eventually due to multiple close passes to Jupiter, deep into its radiation belts—a reminder that space is hard.

But it’s worth exploring.

Support our core enterprises

Your support powers our mission to explore worlds, find life, and defend Earth. You make all the difference when you make a gift. Give today!

Donate

Explore Worlds

Explore Worlds Find Life

Find Life Defend Earth

Defend Earth